Description

The K3HS is a high speed small hole driller EDM machine that drills difficult to cut carbide and heat treated workpieces. The K3HS is often used as a production machine to EDM start holes in die plates and is sometimes combined with an auxiliary axis to index or rotate a workpiece.

Features

- AEF (Automatic Electrode Feeder)

- Workpiece Clamping Kit

- W-Axis

- Diffuser-Shaping “Loran” Capabilities

- New LK2/LK20 Control

- Energy Saving Circuit

Options

- Amp Booster

Specifications

| X - Axis Travel | 11.81” (300 mm) |

| Y - Axis Travel | 15.75” (400 mm) |

| Z - Axis Travel | 11.81” (300 mm) |

| W - Axis Travel | 9.06” (230 mm) |

| X-Y-W Axis Servo System | AC Servo Motor |

| Z Axis Motor | Micro Step Pulse Motor |

| Electrode Diameter | Φ.010” ~ .12” (Φ.25 ~ 3 mm) |

| Work Table Size | 15.75” x 17.72” (400 x 450 mm) |

| Distance From Guide to Table | 10.63” ~ 19.69” (270 ~ 500 mm) |

| Machine Dimensions | 56.10” x 44.09” x 81.89” (1,425 x 1,120 x 2,080 mm) |

| Max. Workpiece Weight | 440.9 lbs (200 kg) |

| Machine Weight | 1,873.9 lbs (850 kg) |

High Speed Drilling

Since the K3HS hole popper is equipped with K-SMC, Sodick Motion Controller, the optimized servo control is activated and improves cutting speed by up to 200%.

Fine Feeding

Accurate fine feeding is controlled for stable machining.

Eco-Friendly

The K Series features energy-saving designs and technologies. Compared to conventional Hole Drillers, the K3HS can reduce average energy consumption by up to 60%.

LN Assist

An automatic programming system, LN Assist, is standard on the K3HS. Its simplified graphics screen allows for easy operation. As LN assist is also capable of a series of calculations and macro functions, operators can easily work with any kind of complex cutting layouts and programs not dependent on their skills. A customized function is available where operators can register their own programs as a utility.

AEF

Standard on the K3HS, Sodick’s automatic electrode feeder enables continuous cutting with multiple electrodes for unattended machining. The Sodick AEF is capable of handling electrodes between 0.02” and 0.12” in diameter, with variable capacity, up to 40 electrodes at ø0.02”

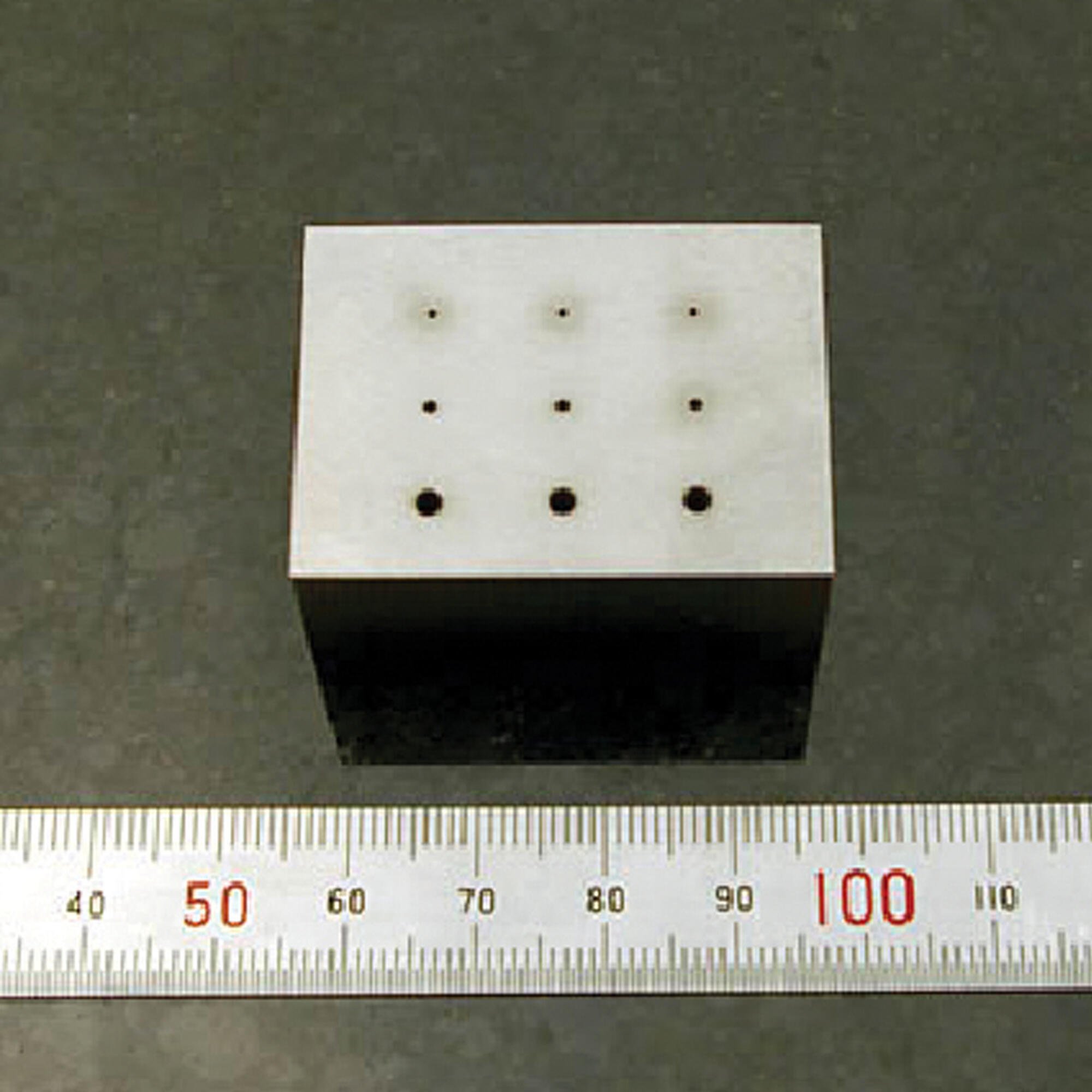

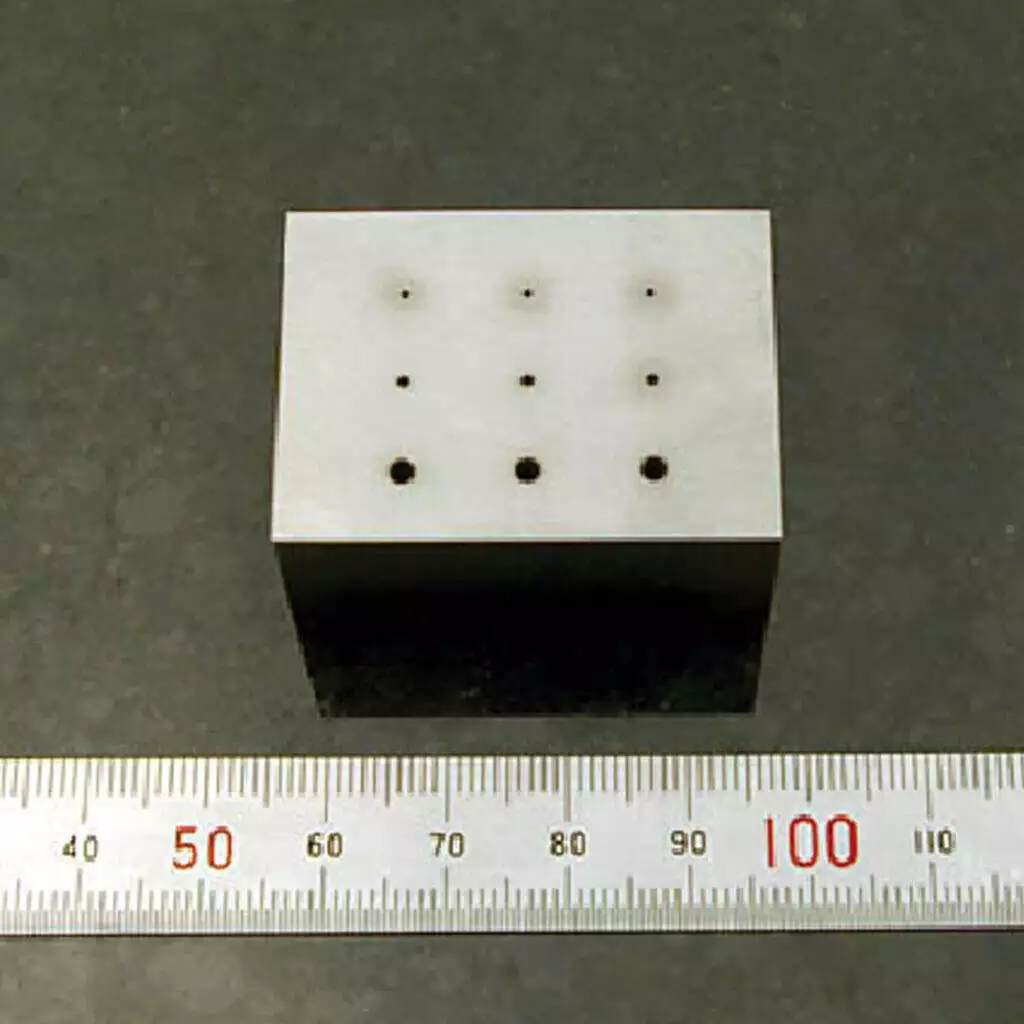

Samples

Material: STAVAX

Thickness: .79” (20 mm)

Electrode Material: Copper (Cu) Pipe

Electrode Diameter: Φ0.02” (Φ0.5 mm), Φ 0.039” (Φ1.0 mm), Φ 0.079” (Φ2.0 mm)

Dielectric Fluid: Water